Key Robotics Trends Shaping the Future in the US

Key trends shaping the future of robotics in the US include advancements in AI and machine learning, increasing automation across industries, and the development of collaborative robots (cobots) for enhanced human-machine interaction.

The robotics industry in the United States is undergoing a rapid transformation, driven by technological advancements and increasing demand across various sectors. Understanding what are the key trends shaping the future of robotics in the US is crucial for businesses, researchers, and policymakers alike. These trends are not only revolutionizing how tasks are performed but also creating new opportunities and challenges for the workforce.

Artificial Intelligence and Machine Learning Integration

One of the most significant trends in US robotics is the integration of artificial intelligence (AI) and machine learning (ML). This integration is enhancing the capabilities of robots, allowing them to perform more complex tasks with greater autonomy.

Enhanced Autonomy

AI and ML algorithms enable robots to learn from data, adapt to changing environments, and make decisions without human intervention. This enhanced autonomy is particularly valuable in industries such as manufacturing and logistics, where robots can perform repetitive tasks with increased efficiency.

Predictive Maintenance

AI-powered predictive maintenance is another key application. By analyzing sensor data from robots, AI algorithms can identify potential failures before they occur, reducing downtime and maintenance costs.

- Increased Efficiency: AI-driven robots can optimize their movements and actions to minimize energy consumption and maximize throughput.

- Improved Accuracy: Machine learning algorithms can fine-tune robot performance, leading to more accurate and consistent results.

- Real-time Decision Making: AI enables robots to make real-time decisions based on sensory input, allowing them to respond quickly to changing conditions.

- Data Analysis: AI can analyze large datasets to identify patterns and insights that can be used to improve robot design and performance.

The convergence of AI and robotics is not just about automating tasks; it’s about creating intelligent systems that can work alongside humans to solve complex problems, making them indispensable assets in various industries.

Increasing Automation Across Industries

Automation is no longer limited to manufacturing. Industries across the United States are increasingly adopting robotics to improve efficiency, reduce costs, and enhance safety. This trend is evident in sectors ranging from healthcare to agriculture.

Healthcare Robotics

In healthcare, robots are being used for surgery, rehabilitation, and even dispensing medication. Surgical robots offer greater precision and control, leading to improved patient outcomes. Rehabilitation robots assist patients in regaining mobility and strength.

Agricultural Robotics

Agricultural robots are automating tasks such as planting, harvesting, and crop monitoring. These robots can work around the clock, increasing productivity and reducing the need for manual labor.

- Precision Agriculture: Robots can precisely apply fertilizers and pesticides, reducing waste and minimizing environmental impact.

- Automated Harvesting: Robots can identify and harvest ripe crops, reducing labor costs and improving efficiency.

- Remote Monitoring: Drones and robots can monitor crop health and identify potential problems, allowing farmers to take timely action.

The expansion of automation across industries is driven by the need to improve productivity and efficiency. Robotics offers a powerful tool for achieving these goals, leading to significant cost savings and improved outcomes.

Beyond these sectors, logistics and warehousing are also experiencing significant automation, with robots handling tasks like sorting, picking, and packing, streamlining operations and reducing error rates.

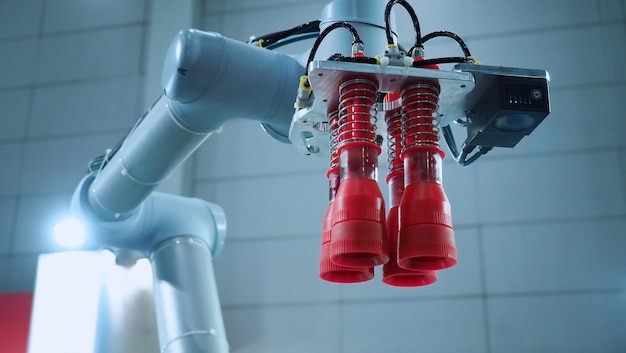

Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work alongside humans in shared workspaces. Unlike traditional industrial robots that are typically caged off for safety reasons, cobots are equipped with sensors and safety features that allow them to operate safely in close proximity to humans.

Enhanced Safety

Cobots are equipped with force sensors and vision systems that allow them to detect human presence and avoid collisions. This enhanced safety makes them suitable for a wide range of applications in manufacturing, healthcare, and logistics.

Increased Flexibility

Cobots are typically smaller and more flexible than traditional industrial robots. They can be easily programmed and reconfigured to perform different tasks, making them ideal for small and medium-sized enterprises (SMEs).

- Easy Programming: Cobots can be programmed using intuitive interfaces, reducing the need for specialized programming skills.

- Flexible Deployment: Cobots can be easily moved and redeployed to different locations within a facility.

- Improved Ergonomics: Cobots can assist humans with physically demanding tasks, reducing the risk of injury and improving ergonomics.

The rise of cobots is transforming the way humans and robots interact in the workplace. By working together, humans and cobots can leverage their respective strengths to achieve greater productivity and efficiency.

Supply Chain Optimization

Robotics plays a vital role in optimizing supply chain operations across the United States. From warehouses to transportation, robots are streamlining processes and improving efficiency.

Warehouse Automation

Robots are being used in warehouses to automate tasks such as sorting, picking, and packing. These robots can work around the clock, reducing labor costs and improving throughput.

Autonomous Transportation

Self-driving trucks and delivery robots are being tested and deployed to automate transportation tasks. These autonomous vehicles can reduce transportation costs and improve delivery times.

- Real-time Tracking: Robots can track inventory in real-time, providing valuable insights into supply chain performance.

- Reduced Errors: Automated processes reduce the risk of human error, leading to improved accuracy and reliability.

- Faster Delivery: Autonomous vehicles can deliver goods faster and more efficiently than traditional methods.

The integration of robotics into supply chain operations is transforming the way goods are moved and delivered. By automating key processes, companies can reduce costs, improve efficiency, and enhance customer service.

The data-driven insights from these robotic systems also enable companies to make informed decisions, optimizing routes, inventory levels, and staffing to meet fluctuating demands effectively.

Advancements in Sensor Technology

Advancements in sensor technology are enabling robots to perceive their environment with greater accuracy and detail. These sensors provide robots with the data they need to navigate, interact with objects, and make decisions.

3D Vision Systems

3D vision systems allow robots to “see” their environment in three dimensions. This is particularly useful for tasks such as object recognition, obstacle avoidance, and navigation.

Force Sensors

Force sensors measure the amount of force being applied by a robot. This information can be used to control the robot’s movements and prevent damage to objects or humans.

- Improved Dexterity: Advanced sensors enable robots to perform delicate tasks with greater precision and control.

- Enhanced Safety: Sensors can detect potential hazards and trigger safety mechanisms to prevent accidents.

- Real-time Feedback: Sensors provide real-time feedback on robot performance, allowing for immediate adjustments and improvements.

The ongoing advancements in sensor technology are driving the development of more capable and versatile robots. As sensors become smaller, cheaper, and more powerful, robots will be able to perform an even wider range of tasks.

Lidar (Light Detection and Ranging) technology is also becoming increasingly prevalent, enabling robots to create detailed maps of their surroundings, which is crucial for autonomous navigation in complex environments.

The Role of Government and Investment

Government policies and investment play a crucial role in shaping the future of robotics in the United States. Government initiatives can support research and development, provide incentives for adoption, and address ethical and societal concerns.

Research Grants

Government agencies, such as the National Science Foundation (NSF), provide research grants to support the development of new robotics technologies. These grants help to fund research projects at universities and research institutions.

Tax Incentives

Tax incentives can encourage businesses to invest in robotics. These incentives can take the form of tax credits, deductions, or accelerated depreciation.

- Workforce Development: Government programs can help to train workers for the jobs of the future, ensuring that the US has a skilled workforce to support the robotics industry.

- Ethical Guidelines: Government agencies can develop ethical guidelines for the design and use of robots, addressing concerns about job displacement, privacy, and safety.

- Infrastructure Development: Government investment in infrastructure, such as 5G networks, can support the deployment of robots in various industries.

The government’s role in promoting robotics is multifaceted. By supporting research, providing incentives, and addressing ethical concerns, the government can help to ensure that the US remains a leader in the global robotics industry.

Private sector investment, including venture capital and corporate funding, is also vital, driving innovation and supporting the commercialization of new robotic technologies and startups.

| Key Point | Brief Description |

|---|---|

| 🤖 AI Integration | Enhancing robot autonomy and predictive maintenance. |

| 🏭 Industrial Automation | Increasing efficiency across healthcare, agriculture and logistics. |

| 🤝 Collaborative Robots | Enhancing safety and flexibility in human-robot collaboration. |

| 🚚 Supply Chain | Optimizing logistics with warehouse and transportation automation. |

FAQ

▼

AI empowers robots with advanced decision-making, learning, and adaptation capabilities, enabling them to autonomously perform complex tasks and improve efficiency in various industries such as manufacturing and healthcare.

▼

Collaborative robots, or cobots, are designed to work safely alongside humans in shared workspaces, equipped with sensors and safety features that prevent collisions and injuries, unlike traditional industrial robots.

▼

Industries such as manufacturing, healthcare, agriculture, and logistics are experiencing significant benefits from robotics, including increased efficiency, reduced costs, and enhanced safety in their operations.

▼

Ethical considerations include job displacement, data privacy, and the potential for misuse. These issues require careful consideration and the development of appropriate guidelines and regulations to ensure responsible deployment.

▼

The government supports through research grants, tax incentives, and workforce development programs, fostering innovation and ensuring that the US remains competitive in the global robotics market.

Conclusion

The future of robotics in the US is being shaped by advancements in AI, increasing automation, the rise of cobots, supply chain optimization, and sensor technology. These trends are driving innovation, improving efficiency, and creating new opportunities for businesses and workers alike. With continued investment and collaboration, the US is poised to remain at the forefront of the robotics revolution.